There are so many good reasons to communicate with site visitors. Tell them about sales and new products or update them with tips and information.

Introduction

Plastic injection molding is one of the most widely used manufacturing processes for producing high-volume plastic parts with precision and repeatability. Whether you’re holding a toothbrush, using a medical device, or driving a car, chances are, you’re interacting with components made through plastic injection molding.

In this guide, we’ll explore what plastic injection molding is, how it works, which materials are used, its benefits, limitations, and common applications. Whether you're a product designer, engineer, or manufacturer, understanding the fundamentals of this process can help you make informed decisions about your next project.

What is Plastic Injection Molding?

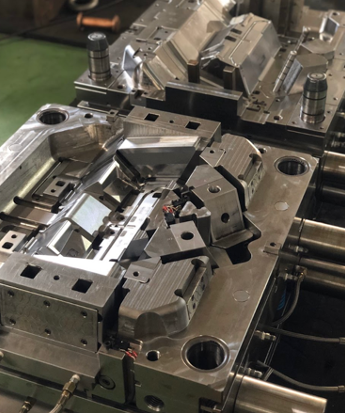

Plastic injection molding is a manufacturing process that involves injecting molten plastic material into a metal mold cavity. Once the plastic cools and solidifies, it takes the shape of the cavity and is ejected as a finished part.

This process is ideal for producing large volumes of identical plastic parts — from small medical components to large automotive housings. The ability to mass-produce high-precision parts makes plastic injection molding a cornerstone of modern manufacturing.

The Injection Molding Process: Step-by-Step

1. Mold Clamping: The two halves of the mold — the cavity and core — are clamped together securely using high-pressure systems.

2. Injection: Plastic pellets (typically thermoplastics) are heated until molten and then injected into the mold through a screw or plunger under high pressure.

3. Cooling: As the molten plastic fills the cavity, it begins to cool and solidify, taking the form of the desired part.

4. Ejection: Once cooled, ejector pins push the part out of the mold, and the cycle repeats.

5. Post-processing: Some parts may require secondary processes such as trimming, polishing, painting, or ultrasonic welding.

Materials Used in Plastic Injection Molding

A wide range of thermoplastics are used in plastic injection molding, depending on the desired properties of the end product. Common materials include:

- ABS (Acrylonitrile Butadiene Styrene): Strong, impact-resistant; used in automotive and consumer products.

- PP (Polypropylene): Chemical resistance, flexible; used in packaging and medical applications.

- PC (Polycarbonate): High strength, optical clarity; used for lenses and electronic enclosures.

- PA (Nylon): Durable, wear-resistant; used in gears and mechanical parts.

- TPE/TPU: Flexible, rubber-like; used in seals, grips, wearable tech.

Key Advantages of Plastic Injection Molding

✔ High Efficiency: Once the mold is made, production is fast — often seconds per part.

✔ Cost-Effective at High Volumes: Though mold tooling is expensive, unit cost drops significantly with volume.

✔ Complex Geometry Support: Advanced mold design enables production of complex shapes with tight tolerances.

✔ Consistency & Repeatability: Injection molding produces thousands or millions of parts with identical dimensions.

✔ Wide Range of Materials: Various thermoplastics and thermoplastic elastomers can be used.

✔ Surface Finishes & Aesthetics: Parts can be molded with different colors, textures, and finishes without post-processing.

Applications of Plastic Injection Molding

Medical Devices: Syringes, diagnostic components, enclosures for electronics, surgical instrument housings.

Automotive Industry: Light guides and lenses, dashboard components, fluid reservoirs and brackets.

Consumer Electronics: Remote control shells, laptop and phone casings, cable connectors.

Smart Home & IoT: Sensor housings, wall mounts, switch covers.

Industrial Equipment: Tool handles, enclosures, mounting components.

Design Considerations for Plastic Injection Molding

To optimize cost, performance, and manufacturability, designers must account for:

- Wall Thickness: Uniform thickness helps avoid warping or sink marks.

- Draft Angles: Tapered walls allow easy part ejection.

- Ribs & Gussets: Enhance structural integrity without adding bulk.

- Material Flow: Design must allow for even flow during injection to avoid defects.

- Gate Placement: The location where plastic enters affects aesthetics and strength.

Types of Plastic Injection Molding

- Two-Shot (Double Injection) Molding: Allows for multi-material or multi-color parts.

- Insert Molding: Embeds metal or other parts into plastic.

- Overmolding: Combines two materials for comfort or protection.

- Gas-Assisted Molding: Creates hollow sections with less material.

Challenges and Limitations

While versatile, plastic injection molding is not without its challenges:

- High Initial Tooling Cost: Custom molds are expensive.

- Lead Time for Mold Fabrication: Tooling can take weeks to design and manufacture.

- Design Changes Are Costly: Once the mold is made, changes are expensive.

For low-volume production or prototypes, alternatives like 3D printing or CNC machining may be more cost-effective.

Future Trends in Plastic Injection Molding

🌐 Industry 4.0 Integration: Real-time monitoring, predictive maintenance, automated production lines.

🌱 Eco-Friendly Materials: Biodegradable plastics, recycled thermoplastics.

🧠 AI-Driven Quality Control: Automated defect detection, intelligent process optimization.

Conclusion

Plastic injection molding remains a dominant method in the global manufacturing landscape. Its balance of speed, scalability, and precision makes it essential for industries ranging from automotive to healthcare.

For manufacturers, designers, and engineers looking to produce high-quality plastic parts, understanding the principles, benefits, and considerations of plastic injection molding is critical to success.

Call to Action

If you're searching for a reliable plastic injection molding partner with decades of experience, high-precision capabilities, and industry-specific expertise — Long Team Industrial Co., Ltd. offers end-to-end solutions from custom mold design to mass production and post-processing.

With over 37 years of experience, ISO/IATF certifications, and advanced AIoT integration, we help you turn ideas into market-ready products with speed and precision.

📩 Get a Quote Now | 📞 Contact us today to discuss your project needs.