Precision Double Injection Molding ServicesPrecision Double Injection Molding Services

Unlocking the Power of Double Injection Molding

Double injection molding, often referred to as two-shot molding or dual-shot injection, is a powerful technique used to manufacture plastic parts composed of two different materials or colors in a single process. For brands and assemblers unfamiliar with this method, it may seem complicated or costly at first glance. However, the strategic benefits of product enhancement, cost savings, and manufacturing efficiency far outweigh the initial investment—if executed correctly.

This guide aims to help decision-makers better understand the potential of double injection molding, from design concepts and material selection to tooling quality and project planning.

What is Double Injection Molding?

Double injection molding is a highly specialized process where two different thermoplastic materials are molded into a single, unified component. Unlike overmolding—where the second material is layered onto an existing part—two-shot molding happens within the same machine, utilizing two barrels and a rotating or sliding mold mechanism.

Key Characteristics:

- Two materials, one process

- No secondary bonding steps

- Perfect for complex parts that require dual textures, softness, or colors

- Reduces post-processing and labor

Common Applications:

- Automotive parts: dashboards, knobs, light guides

- Medical devices: ergonomic handles, seals

- Consumer electronics: remote controls, protective casings

- Home appliances: buttons, grips, color accents

Is Your Product Right for Double Injection?

Before investing in dual-shot molding, it’s crucial to determine if your product design and usage context benefit from the process.

Ideal Use Cases:

- Need for soft touch or grip: Tools, toothbrushes, medical instruments

- Multi-color branding: Consumer products where brand colors enhance user experience

- Integration of functions: Combining flexible and rigid components in one part

- Precision requirements: Medical housings or optical components with tight tolerances

Key Questions to Ask:

- Can dual materials improve the product’s function or appeal?

- Would it reduce the number of parts or assembly steps?

- Does your production volume justify the mold cost?

When these align, double injection molding can deliver long-term ROI and faster market entry.

How Double Injection Molding Works (Step-by-Step)

Understanding the process will help teams align on what to expect from tooling and production.

Step 1: Mold Design & Material Selection

The two-shot mold has two cavities or sections: one for each material. Engineers simulate flow paths, shrinkage, and bonding surfaces to avoid warping or defects.

Step 2: First Injection (Base Material)

The first material is injected into the mold to form the base structure of the part.

Step 3: Mold Rotation or Sliding

The mold then rotates or shifts, aligning the part for the second shot without removing it.

Step 4: Second Injection (Overlapping Material)

The second material is injected over or around the first part, forming a chemically or mechanically bonded final product.

Step 5: Cooling & Ejection

The part is cooled, ejected, and ready for inspection.

This automated cycle minimizes human labor and ensures consistency.

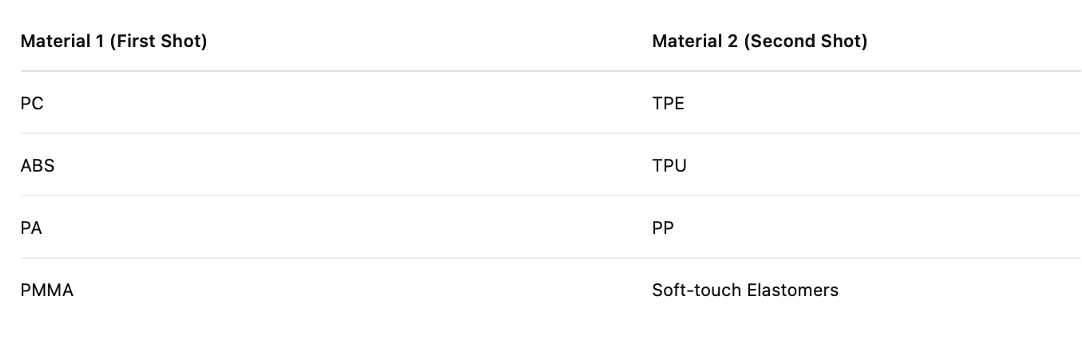

Selecting the Right Materials for Two-Shot Molding

Not all materials work well together. Choosing compatible plastics is critical for bonding, durability, and functionality.

Factors to Consider:

- Adhesion: Will the materials bond chemically or require mechanical locking?

- Processing Temperatures: Can both plastics be molded without degrading?

- Hardness/Flexibility Balance: Match product usage (grip vs. support)

- Shrinkage Rates: Prevent deformation or warping

Recommended Material Pairs:

It’s best to run pilot trials and consult with a compounder or molding expert to test adhesion and flow properties.

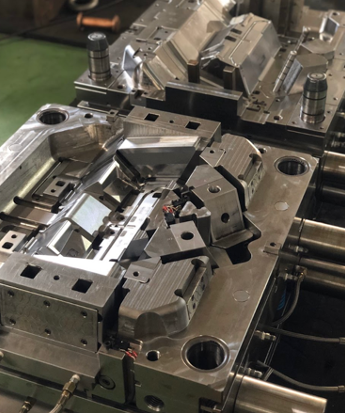

The Role of High-Precision Molds in Two-Shot Success

High-quality tooling is the cornerstone of successful double injection molding. These molds are inherently more complex than single-shot tools.

Tooling Considerations:

- Rotary or Sliding Systems: Must be precise and durable for repeat cycles

- Gate Design: Prevents material leakage or incomplete fill

- Thermal Control: Multi-zone temperature regulation for different materials

- Parting Lines: Designed to avoid visible seams or flash

Mold Failure Risks (If Quality is Neglected):

- Inconsistent material bonding

- Excessive wear and poor alignment

- Mold leakage or damage

- Part rejection and costly downtime

Pro tip: Choose mold manufacturers with dual-shot experience and invest in hardened tool steel (like H13 or S136).

Cost-Benefit Analysis: Is It Worth It?

Yes, two-shot molds are more expensive—often 30–50% more than single-shot tools. But the long-term savings and benefits often outweigh the initial cost.

Cost Drivers:

- Tooling complexity and lead time

- Machine requirements (dual-barrel)

- Material cost (TPEs are pricier than rigid plastics)

Offsetting Benefits:

- Eliminates secondary assembly processes

- Reduces part count and inventory

- Enhances product value and marketability

- Speeds up production cycle time

Brands using dual-shot molding often report faster market launches and increased customer satisfaction.

Partnering with the Right Manufacturer

If you’re new to double injection molding, your success will hinge on the expertise and support of your manufacturing partner.

What to Look For:

- Proven experience with two-shot mold design and production

- Access to 2K/2-shot injection machines (80T–850T range)

- Full-service capabilities: DFM, rapid prototyping, mold simulation

- Certifications (ISO 9001, IATF 16949) for quality assurance

Getting Started with Confidence

As you evaluate the feasibility of double injection molding, ask your team:

- Have we identified parts that can be improved with two materials?

- Do we have a clear design intent for dual-shot functionality?

- Are we working with a partner that can support mold development, testing, and scale-up?